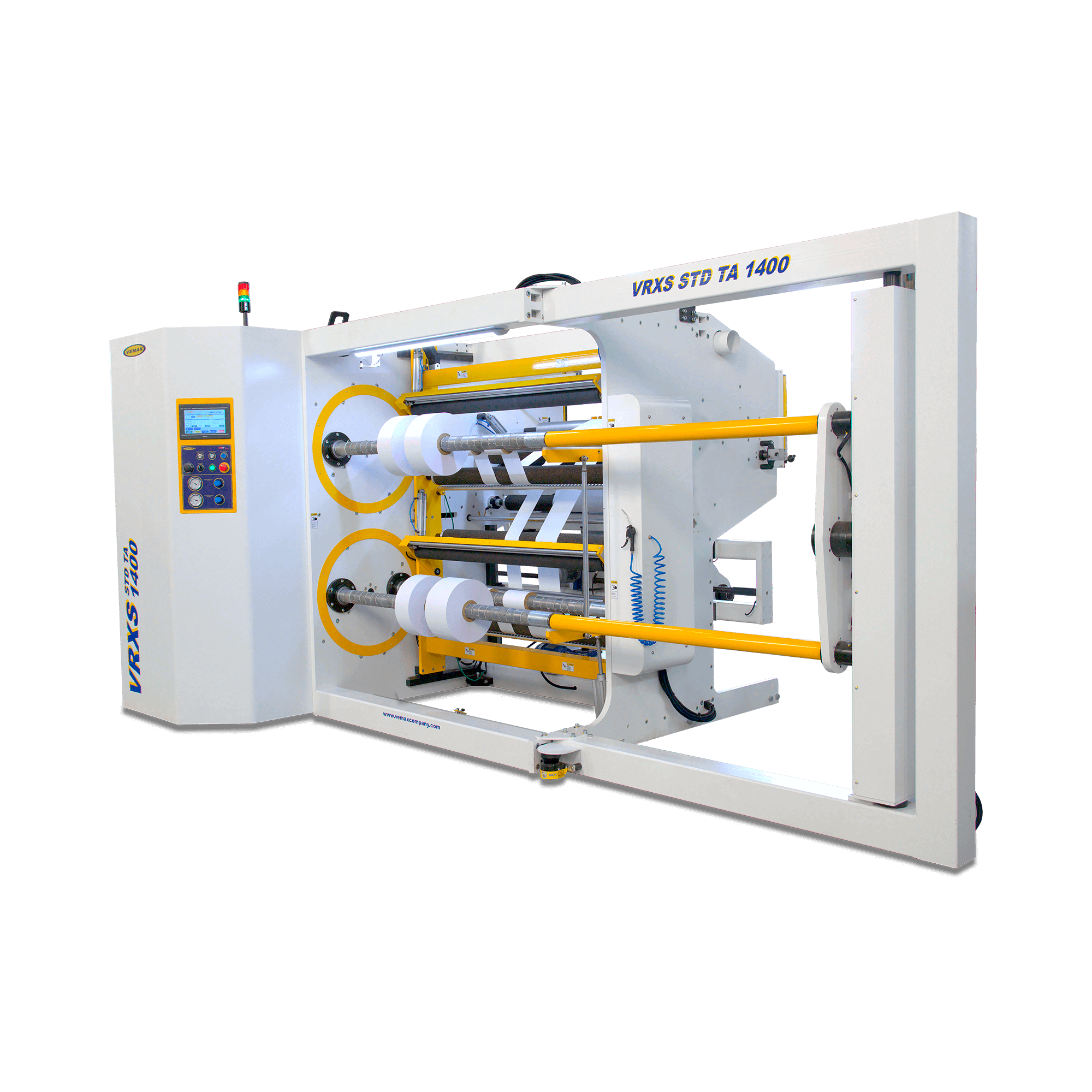

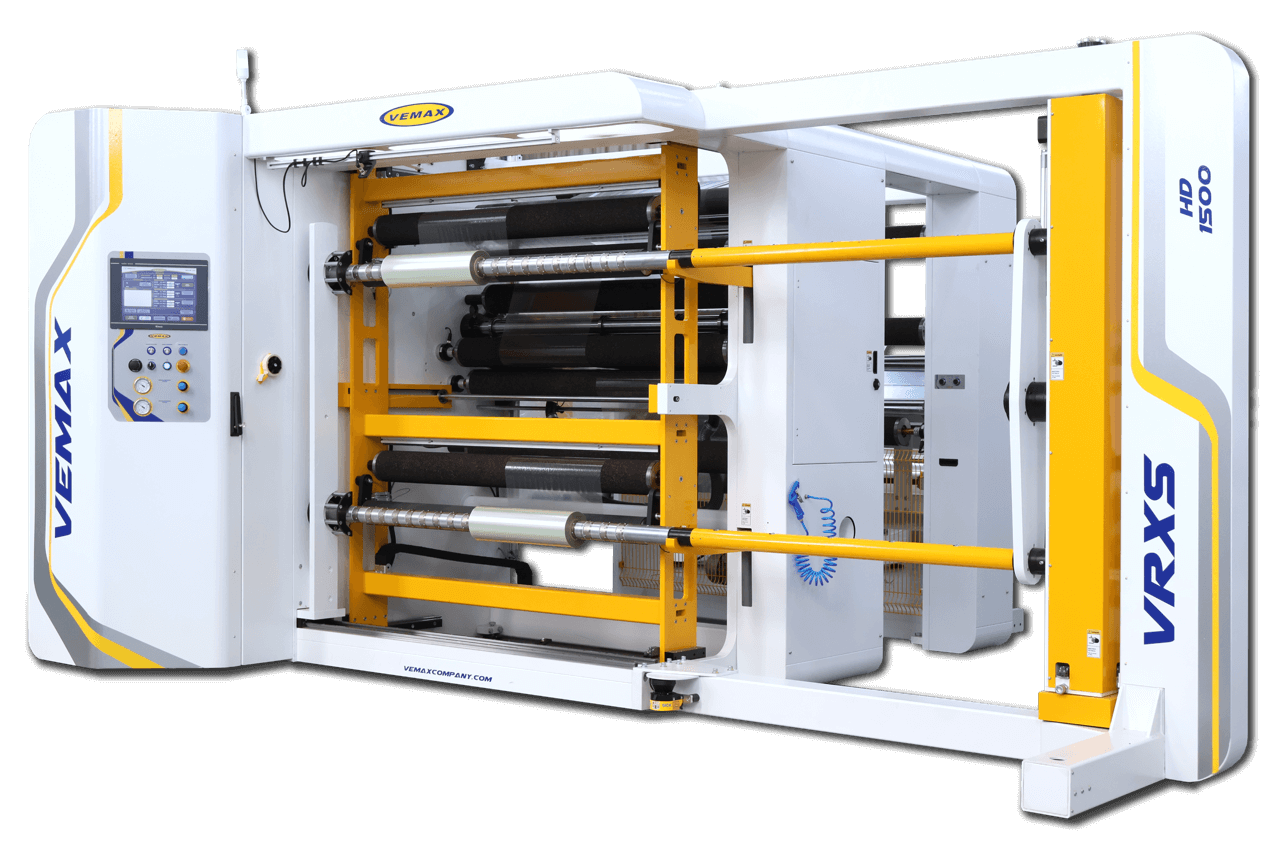

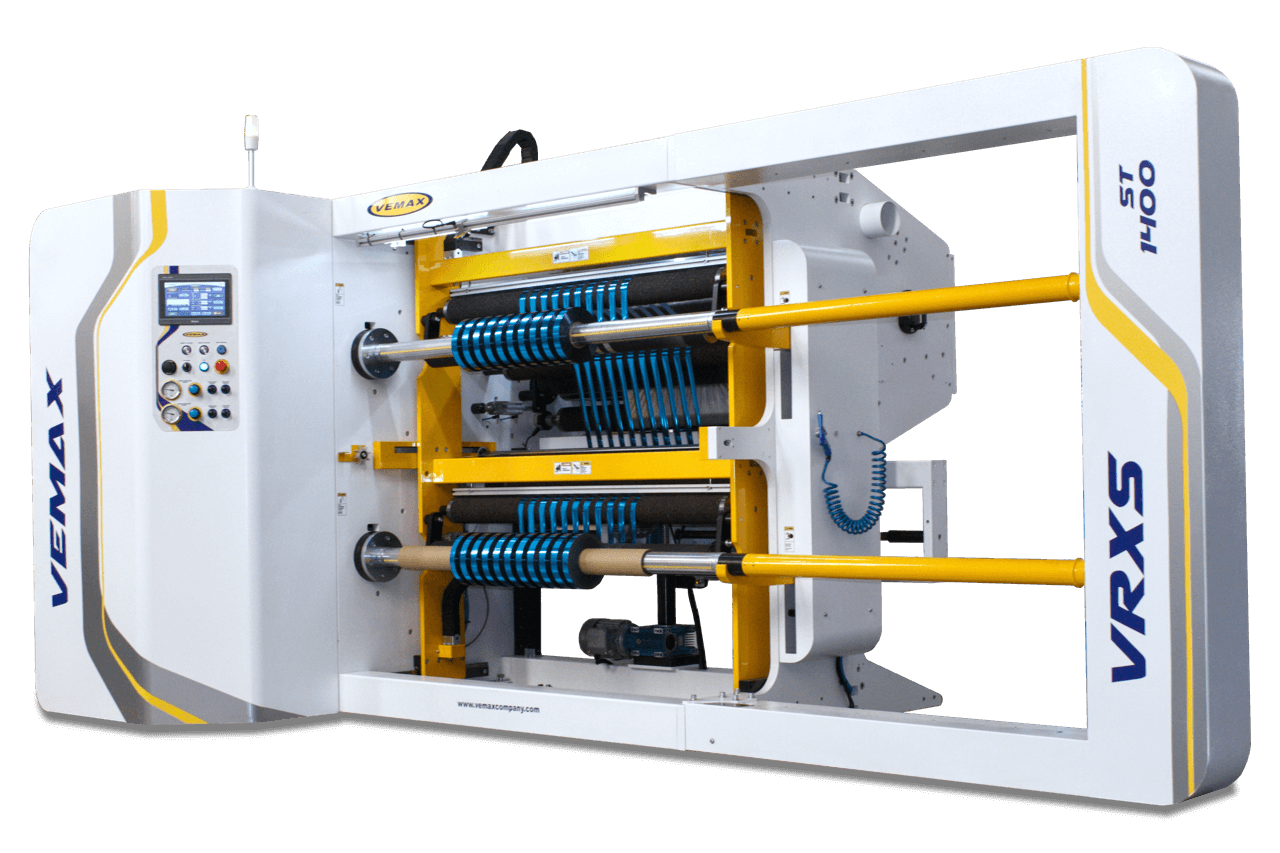

SIC (System Integrated Control) with HMI 10”

Automatic exchange head. Dual-disk type shaft rewinders driven by a DC motor and reducer, with automatic stop for exchange and precision in automatic cutting.

Pneumatic compactors with rubber idlers automatically activated, with retraction by an inductive distance sensor. This allows maximum compaction with alignment for the rolls.

Precise Taper control with linear or exponential tension curve, providing greater precision in tension control for challenging materials such as self-adhesives with liner and laminates.

Rewinder shafts use 50mm standard or 25 mm optional "differential" (Quick lock ball friction). Exclusive anti-leakage system design for greater precision and quality in work with materials of different grammage.

Core positioners with laser automatically positioned with decimal measurement programming through the HMI and a simple touch on the sensor, allowing greater fleibility for the preparation.

Independent Chucked unwinder with closing and lifting system. Robust and reliable design.

Robotic Roll Extractor with Axis rotation and body rotation optional.