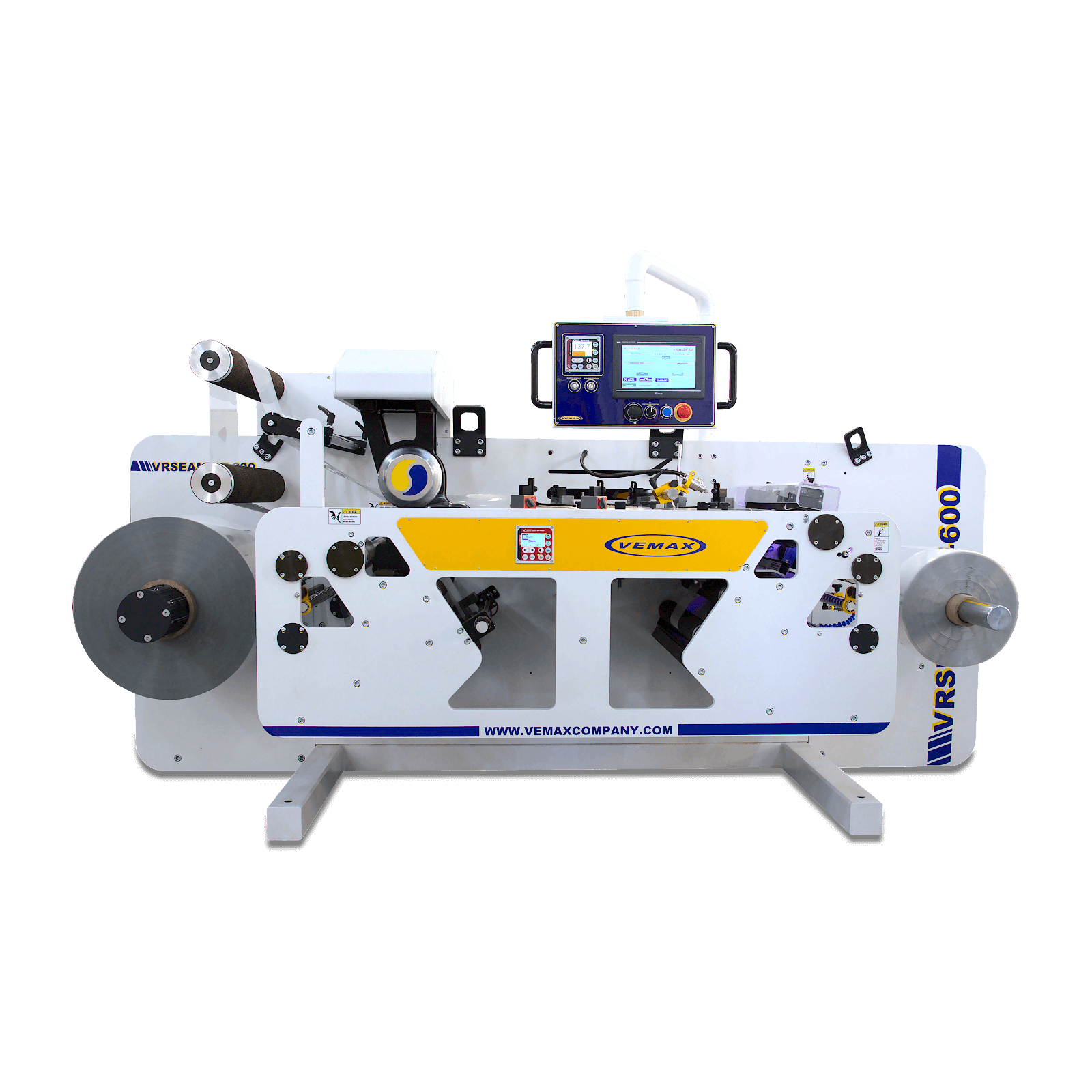

Independent automatic voltage control in the HMI of the unwinder and rewinders with load cells, proportional valve and ultrasonic diameter sensor

SIC (System Integrated Control) with HMI 10”

Minimum Lay Flat: 50 mm (tolerance +-0.5mm)

Maximum Lay Flat: 305mm (tolerance +-0.5mm)

Designed for quick setup and ergonomic vertical inspection position.

Automatic randomizer on the rewinder with continuous, variable or intermittent programmable displacement control.

Automatic Lay flat monitoring system with sound and light warning and 300mm BST ultrasonic sensor.

IONTECH Shockless Anti-Static Bar.

Blower nozzle to monitor welding on the rewinder.

Pressurized reservoir for solvent storage, electronically controlled with valve.

NORDSON brand high precision solvent metering nozzle with applicator needle and electronically controlled with variable flow, synchronized with the line speed.

High precision anti-burr solvent application system.

Laser sensor for end of web control with automatic stop programmable by diameter.