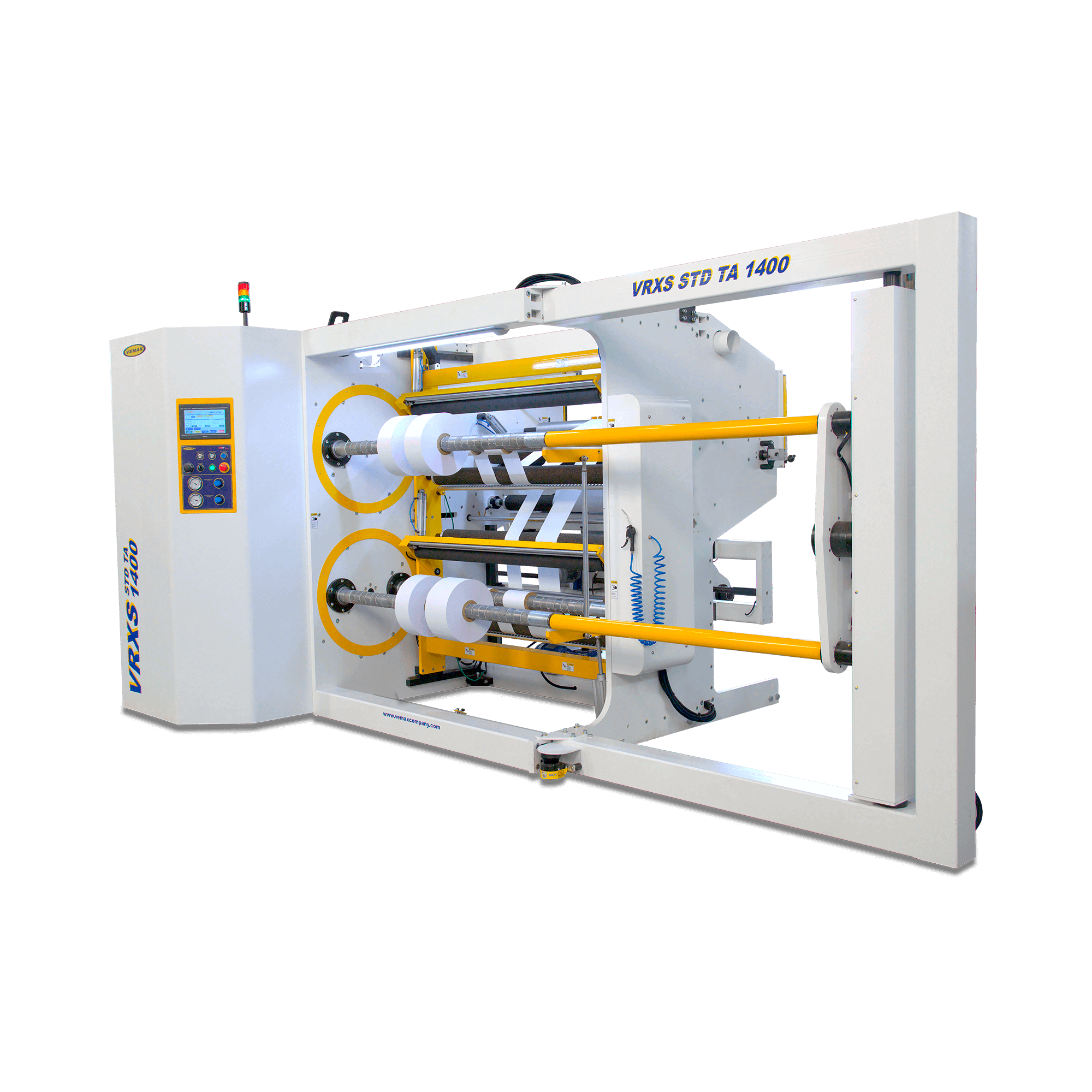

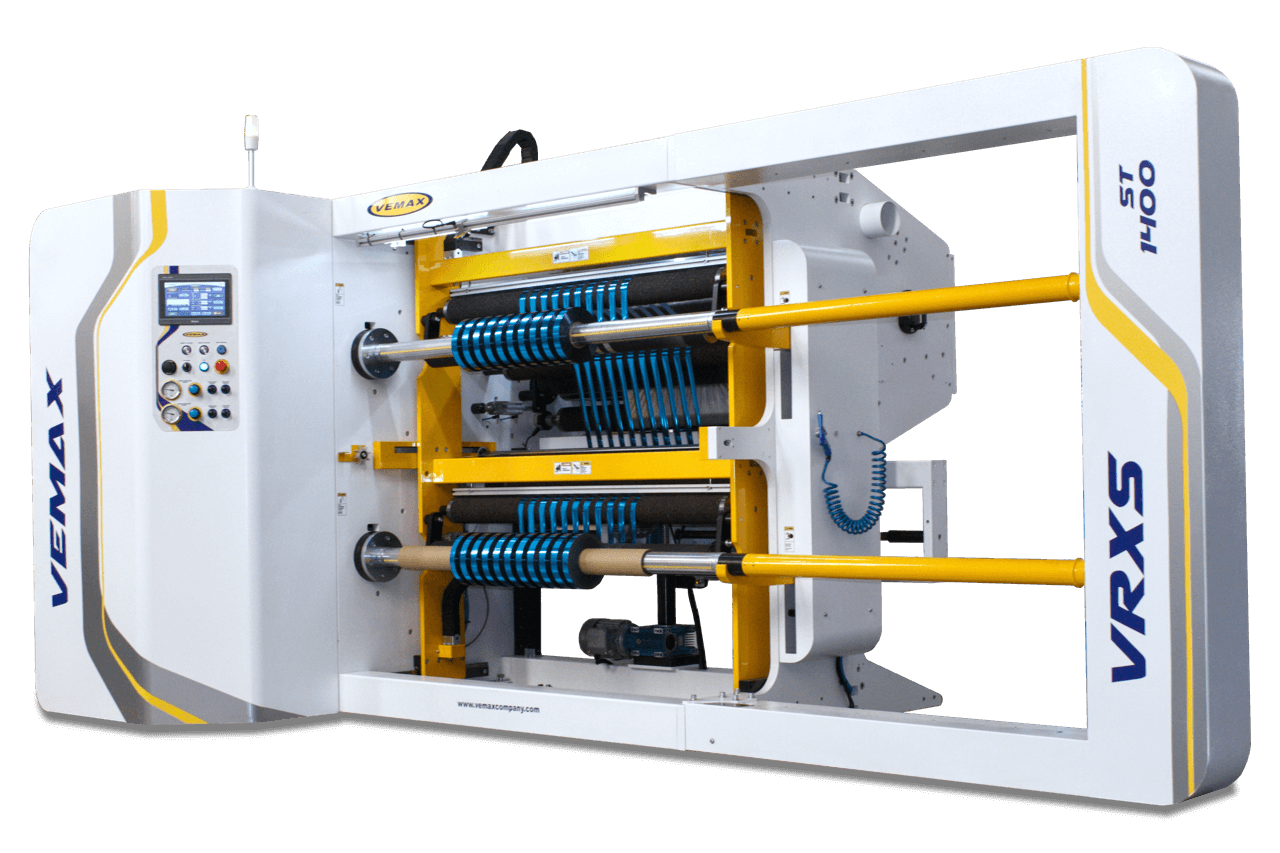

Unique Vemax Compactor System using an idler compactor to allow working with materials of varying weight and rolls having different diameters on the same shaft while maintaining the correct tension.

SIC (System Integrated Control) with HMI 10”

Laser core positioning system automatically sets the sequential or variable decimal measurement through programming the HMI.

Rewinder shafts of "Differential" type ("Quick lock" ball friction) of 50mm and chrome steel balls. Unique anti-wrinkle system design for greater precision and quality in working with materials with weight difference. This system works with speed and slip system controlled through a pneumatic system with electronic proportional valves.

Independent chucked unwinder with clamping and lifting system fixed on linear roller guides that are driven with geared motors, spindles and chucks.

Robotized Roll Pusher with Shaft Rotation, Body Rotation and UP/ DOWN movements (Optional)