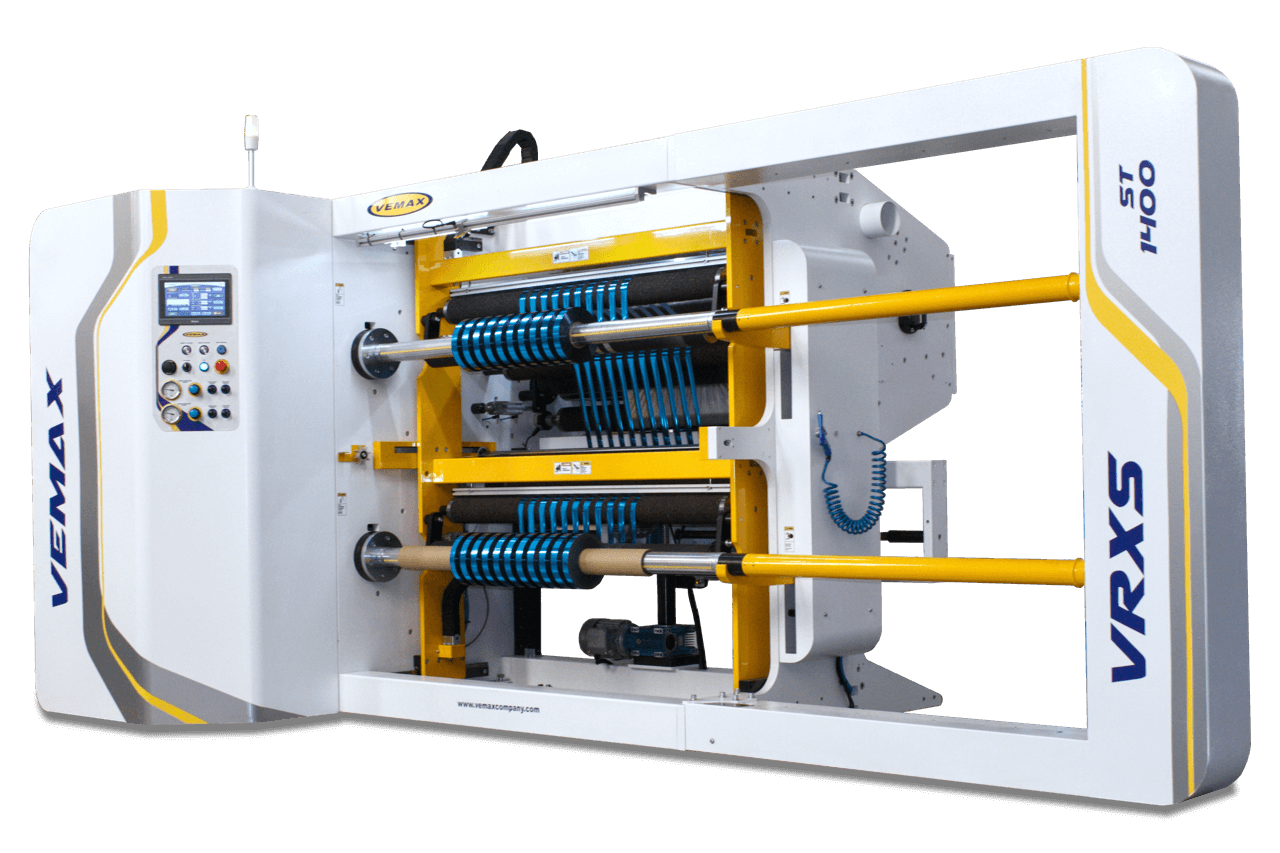

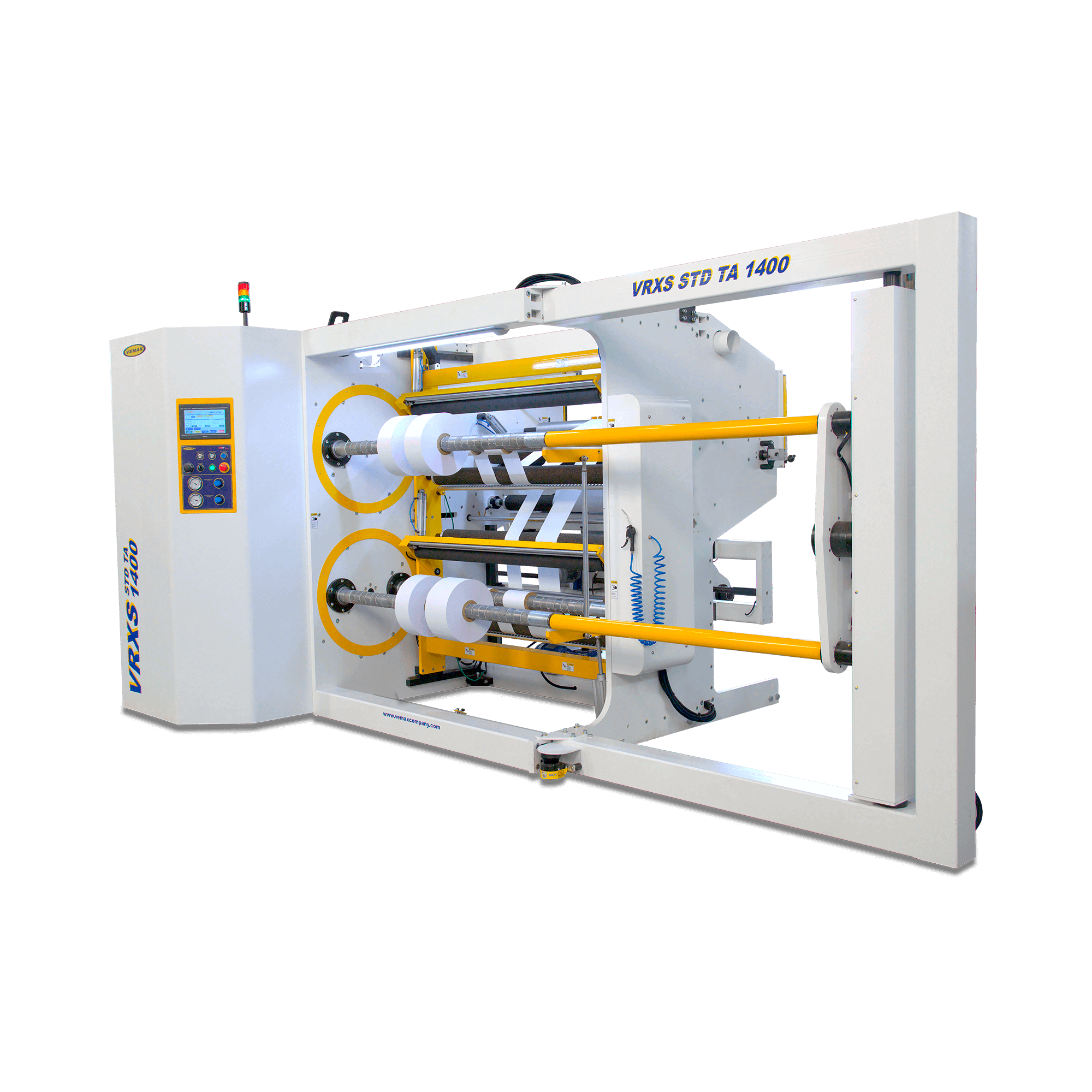

Tension control per load cell 100% in the unwinder and diameter sensor in the rewinder, enabling precise and uniform control on the rolls.

SIC (System Integrated Control) with HMI 10”

Laser sensor for roll detection on rewinder shafts. Safety system that ensures that there are no rolls on the shaft without the support of the support arms.

Rewinder shafts of "Differential" type ("Quick lock" ball friction) of 50mm and chrome steel balls (OPTIONAL).

Independent chucked unwinder with clamping and lifting system fixed on roller linear guides and driven with geared motors, spindles and chestnuts. (OPTIONAL).